In the US the NEC generally only allows one feeder per building so the new feeder would be required to pick up all existing loads to replace the existing feeder including a lighting circuit and a required 120v 20A receptacle circuit. Also, some of your items may be required to have larger circuits. It might turn out that the code requires a larger feed. Note: I am not an electrician and so I may have simplified some things. I'd actually suggest that you run a 100 amp circuit to the sub panel to give you some breathing room so if you end up with, for example, an 80 amp Tesla charger, you don't have to replace the feed wires. You could also start with just the 50 and the 15 and add the others as needed. If you were to exceed 50 amps total at any time, you'd trip the feeding breaker. Also, assuming you didn't want to run multiple devices at once, you could even size the feed wires (and the feeding breaker in the main panel) for the largest device only.įor example, you could have, in the subpanel, a 50 amp breaker for the welder, a 40 amp breaker for the EV charging station (that's enough unless you get a Tesla), a 30 amp breaker for the RV and a 15 amp breaker for the compressor, all fed from a 50 amp circuit.

240V 50 AMP BREAKER INSTALL

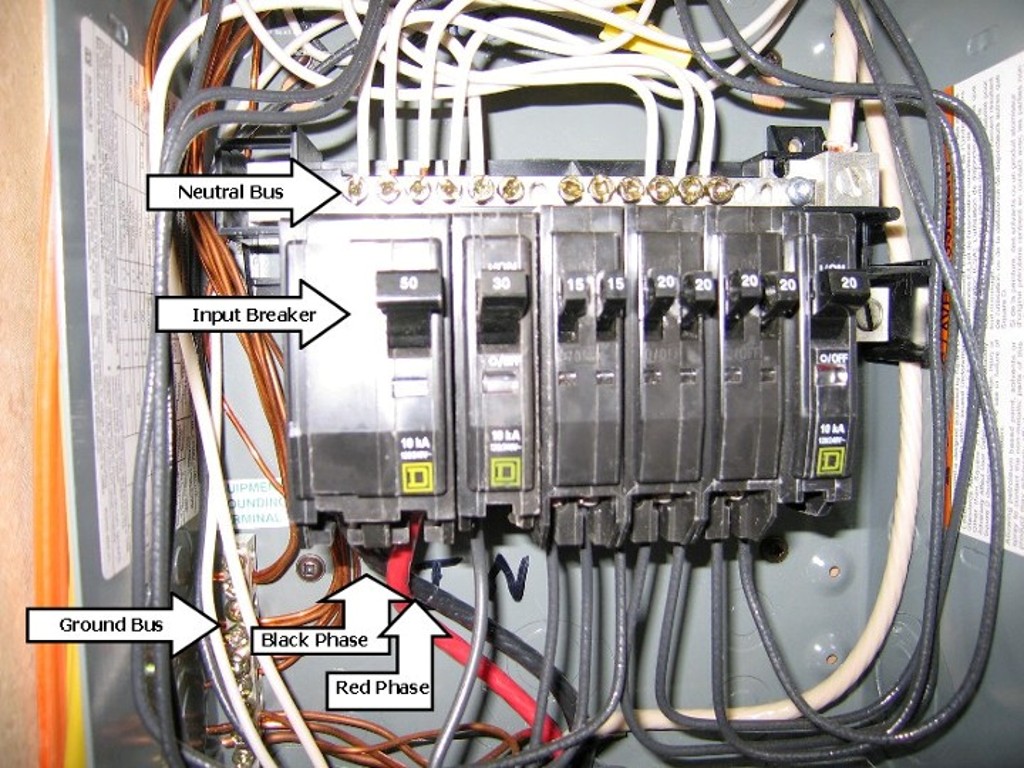

The proper way is to install a sub panel in your garage with separate breakers and outlets for the different amperage devices. If your compressor developed a fault where it was drawing 30 or 40 amps (not a dead short), the breaker would not trip but the cord on the compressor or the motor in the compressor could overheat and catch fire! One thing the other answers have not stated is that the US electrical code does not allow you to plug a 15 amp device into a 50 amp outlet.

0 kommentar(er)

0 kommentar(er)